Navigation

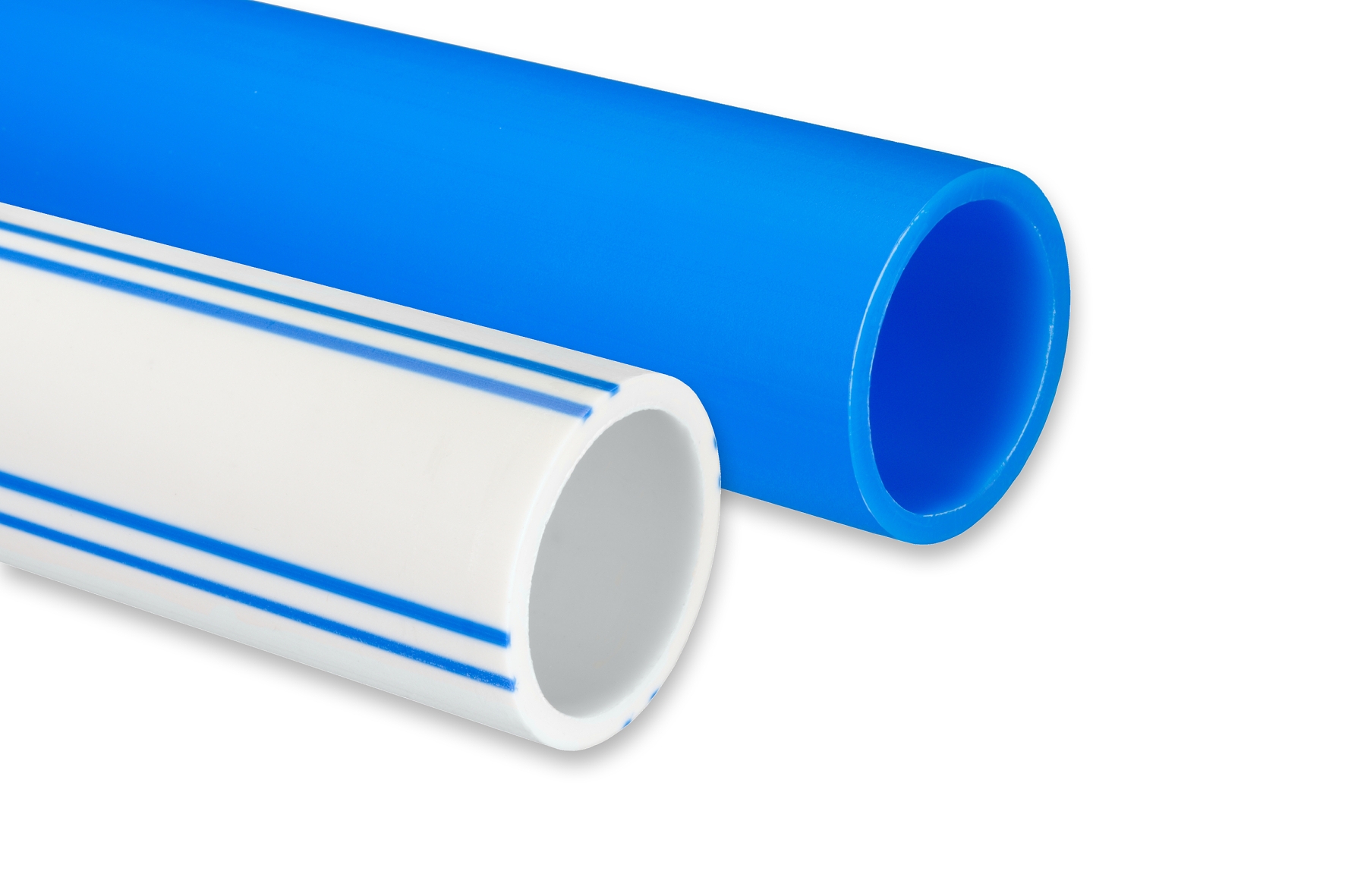

MIKROHARD microtubes

MIKROHARD microtubes

Single wall protective pipes are designed for the latest technology used for optical networks FTTx (Fibre-to-the-X) micro technology.

- microducts can be used for installation in an existing ducts of HDPE tubes (MIKROHARD DI)

- for direct installation in the ground without the use of additional protective tube (MIKROHARD DB)

- various quantities of microtubes can be installed inside OPTOHARD protectors depending on the inner diameter of the protector and the outer diameter of the microtube (these quantities are derived from the need to install microcables with varying numbers of optical fibres)

Design

- standard (DI) - are produced with an inner wall - smooth or grooved, with sliding layer

- hardened (DB) - are produced with an inner wall - smooth or grooved, with sliding layer

Material

- high-density polyethylene (HDPE)

- with UV stabiliser on request

Colour

- according to RAL

Heat resistance

- handling temperature: of +5 ºC to +50 ºC

- operation temperature: of -40 ºC to +70 ºC

- storage temperature: of -40 ºC to +60 ºC

Standard primary microtubes (DI)

- these are designed for installation into existing OPTOHARD protective tubes, both empty and partially full

- installed by blowing or pulling for shorter distances

| outer diameter |

inner diameter |

length of drum |

bend radius |

max. installation tension force at 20 ºC |

max. blowing pressure |

|---|---|---|---|---|---|

| mm | mm | m | mm | N | bar |

| 7 | 5,5 | 2500 | 70 | 200 | 16 |

| 10 | 8 | 2500 | 100 | 380 | 16 |

| 12 | 10 | 2500 | 120 | 490 | 16 |

| 14 | 12 | 1500 | 140 | 500 | 16 |

- for installation into trenches when constructing new access networks without additional protective tubes

- the reinforced walls and mechanical properties of these microducts ensure adequate protection for optical microcables

| outer diameter |

inner diameter |

length on drum |

bend radius |

max. installation tension force at 20 ºC |

max. blowing pressure |

|---|---|---|---|---|---|

| mm | mm | m | mm | N | bar |

| 7 | 3,5 | 2500 | 60 | 390 | 20 |

| 7 | 4 | 2500 | 70 | 350 | 20 |

| 10 | 5,5 | 2500 | 100 | 750 | 20 |

| 12 | 8 | 2000 | 120 | 760 | 20 |

| 14 | 10 | 1500 | 140 | 980 | 20 |

| 16 | 12 | 1250 | 160 | 980 | 15 |

| 20 | 16 | 700 | 500 | 1 000 | 16 |

Packaging

- supplied on drum (front made of plywood, core made of pressed paper)

Drum dimension

| front diameter |

core diameter |

drum width |

bore |

|---|---|---|---|

| mm | mm | mm | mm |

| 900 | 300 | 600 | 75,5 |